We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

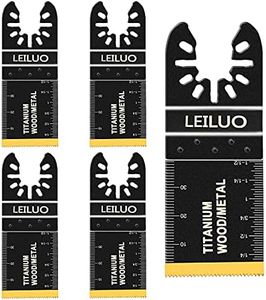

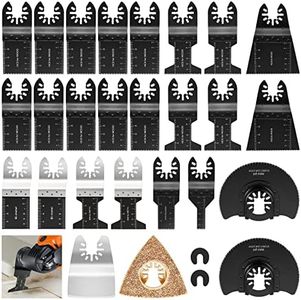

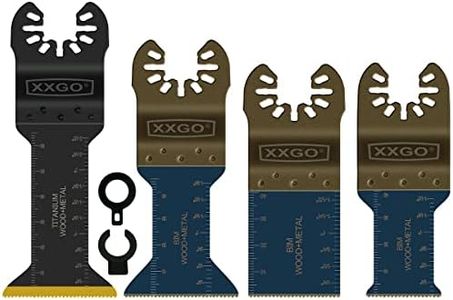

10 Best Oscillating Multitool Blades

From leading brands and best sellers available on the web.Recommended lists

Buying Guide for the Best Oscillating Multitool Blades

Choosing the right oscillating multitool blade is crucial for ensuring efficiency and precision in your projects. These blades are versatile and can be used for a variety of tasks such as cutting, scraping, sanding, and grinding. The key to selecting the right blade lies in understanding the material you will be working with and the specific task you need to accomplish. By focusing on the specifications of the blades, you can ensure that you have the right tool for the job, which will save you time and effort while delivering the best results.MaterialThe material of the blade determines its durability and suitability for different tasks. Common materials include high carbon steel, bi-metal, and carbide. High carbon steel blades are ideal for cutting wood and plastic, offering flexibility and sharpness. Bi-metal blades are more durable and can handle tougher materials like metal and hardwood. Carbide blades are the most robust, suitable for cutting through very hard materials like tile and stone. Choose the blade material based on the hardness and type of material you will be working with.

Blade TypeBlade type refers to the specific design and shape of the blade, which determines its function. There are straight blades for precise cuts, round blades for longer cuts, and segmented blades for cutting in tight spaces. Scraper blades are used for removing old paint or adhesives, while sanding pads are for smoothing surfaces. Consider the task at hand and select a blade type that matches the specific requirements of your project.

Tooth CountThe tooth count on a blade affects the speed and smoothness of the cut. Blades with fewer teeth cut faster but leave a rougher finish, making them suitable for demolition or rough cuts. Blades with more teeth provide a smoother finish and are ideal for detailed work or finishing cuts. Determine whether speed or finish is more important for your project to choose the appropriate tooth count.

Blade WidthBlade width impacts the precision and type of cut you can achieve. Narrow blades are great for detailed work and cutting in tight spaces, while wider blades are better for making long, straight cuts. Consider the size and precision of the cuts you need to make when selecting the blade width.

CompatibilityCompatibility refers to whether the blade can fit your specific oscillating multitool. Some blades are universal and can fit most tools, while others are brand-specific. It's important to check the compatibility of the blade with your tool to ensure a secure fit and optimal performance. Always verify the blade's compatibility with your multitool model before purchasing.