We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

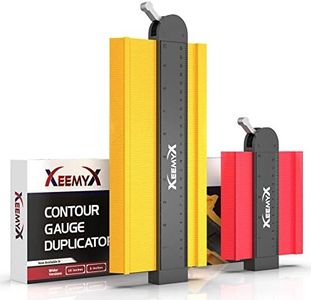

10 Best Contour Gauges

From leading brands and best sellers available on the web.Recommended lists

Buying Guide for the Best Contour Gauges

Contour gauges are essential tools for anyone involved in woodworking, tiling, or any project that requires precise duplication of shapes and profiles. They help you replicate the exact shape of an object, making it easier to cut materials to fit perfectly. When choosing a contour gauge, it's important to consider several key specifications to ensure you get the best fit for your needs.MaterialThe material of the contour gauge affects its durability and precision. Common materials include plastic and metal. Plastic contour gauges are lightweight and affordable, but they may wear out faster and are less durable. Metal contour gauges, often made from stainless steel, are more durable and provide more precise measurements, but they can be heavier and more expensive. If you need a contour gauge for occasional use, a plastic one might suffice. However, for frequent or professional use, a metal contour gauge is a better investment.

Pin DepthPin depth refers to how deep the pins of the contour gauge can go to replicate a shape. This is important because deeper pins can capture more intricate details of the object you are measuring. Pin depths typically range from 2 inches to 5 inches. For general use, a pin depth of around 3 inches is usually sufficient. If you are working with very detailed or deep profiles, you might want to opt for a gauge with a greater pin depth.

WidthThe width of the contour gauge determines how large of an area it can measure in one go. Widths can range from 5 inches to 20 inches or more. A wider gauge can cover more surface area, which is useful for larger projects. However, wider gauges can be bulkier and harder to handle. For small to medium projects, a width of 10 inches is generally adequate. For larger projects, consider a wider gauge to save time and effort.

Locking MechanismA locking mechanism allows the contour gauge to hold the shape after it has been measured, making it easier to transfer the shape to your work material. This is particularly useful for complex shapes that might shift during transfer. Some gauges come with a built-in locking mechanism, while others do not. If precision is crucial for your project, a contour gauge with a locking mechanism is highly recommended.

AccuracyAccuracy refers to how closely the contour gauge can replicate the shape of the object. This is influenced by the thickness and flexibility of the pins. Thinner pins can capture more detailed shapes but may be more fragile. Thicker pins are more durable but may not capture fine details as accurately. For most DIY projects, a standard level of accuracy is sufficient. However, for professional or highly detailed work, look for a gauge with thinner, more precise pins.

![[2 Pack] C](https://images-proxy.bestreviews.guide/2KjC9PEQBkBeX8ntP9YlNzRcGAQ=/0x300/https://m.media-amazon.com/images/I/51XJhPCl+DL._AC_CX679_.jpg)